What Do Special Papers Need To Pay Attention To When Printing?

What Do Special Papers Need To Pay Attention To When Printing?

Because special paper is different from ordinary paper in terms of material, structure and performance, there are also differences in printing process. Need to pay attention to two aspects.

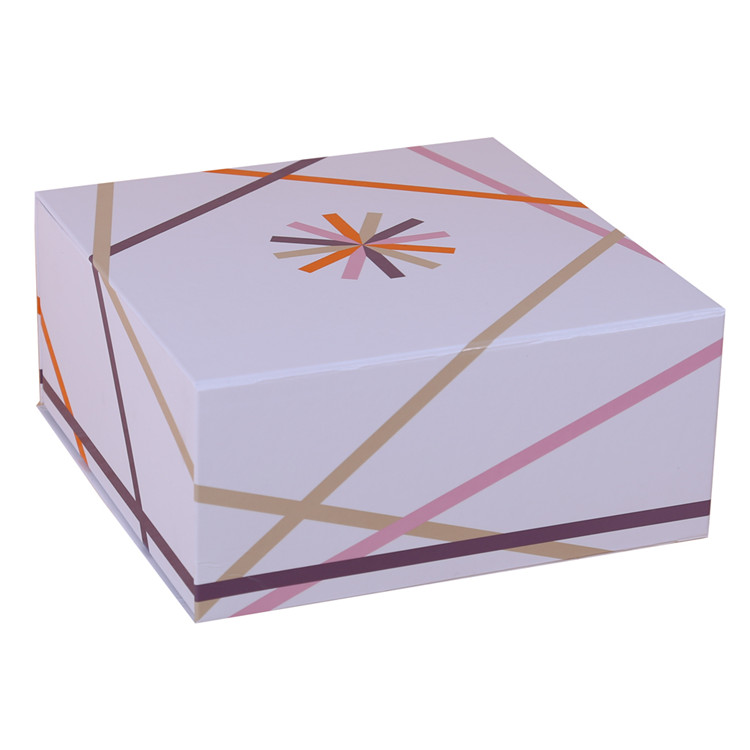

color paper box

First, the difference in the absorption capacity of the ink caused by different structures

paper fo lding box

lding box

Due to the different materials and structures of different types of special papers, some are soft and easy to absorb and dry quickly, while others are hard and tightly structured, the ink does not easily penetrate, and prints take longer to dry. Since the difference in the ink absorption capacity of the special paper used is directly related to the quality of the printed product and the delivery time, special attention should be paid when selecting the use: if the delivery time of the printed matter is urgent, the selected special paper is best not to be printed on the machine, but As a decorative page to enhance the effect of picture albums, or simple processing of paper, such as simple processes such as embossing, embossing, hot stamping, etc., it will not delay the delivery of printed materials. Do not use metal paper that is not easy to dry when the time is tight. Drying time is not enough, it can not achieve the actual effect, but it is self-defeating. For special paper that is easy to absorb ink and has a soft texture, if you use a large area of solid color, you should also pay attention. Because the ink is absorbed too quickly during printing, the surface color is gray and light, and even white spots appear. The effect is not as expected. . Therefore, it is best to apply offset printing samples before use and make sure that they are correct before using.

custom paper box packaging

Second, the difference in surface flatness caused by different textures

lid and base paper box

Due to the different papermaking materials, especially the process, the thickness of special paper is different, and the hardness and softness are also different. Some also have textures, watermarks, etc. The surface flatness of the paper varies greatly. The surface of the paper is slightly rough, the texture is clear, and the texture is good. It is recommended that spot color printing or silk printing be used. Four-color printing is less used. The special structure and texture of the paper are used to fully display the characteristics to achieve the desired effect. Some simple surfaces can also be used. Finishing techniques such as embossing, UV-curable inks, hot stamping, etc. can be icing on the cake. When printing on this type of paper, the ink layer should be thick, the color should be thick, and the visual effect should be more eye-catching.

custom fold able paper box

able paper box

Most of the special papers we commonly see are art papers provided by paper companies for flat or packaging. In fact, there are many types of special papers, such as dust-free paper, oil-absorbing paper, aluminum foil paper, breathable paper and even can be used for printing, such as semi-conductive paper for circuit boards, paper for electronic substrates, etc. The basic principles that designers need to follow are the same, that is, to design pictures and crafts based on different characteristics of the paper. Only by perfect combination with each other can the printed product achieve its proper effect.