Material Types Of Packaging Carton

Material Types Of Packaging Carton

cardboard paper box

Among the four major packaging materials: paper, plastic, metal, and glass, paper packaging materials are the cheapest and can be recycled and reused, which is good for environmental protection and therefore has the fastest development. Common paper products are: food cartons, napkin cartons, cardboard boxes, corrugated boxes, food paper bags, packaging paper barrels, handmade paper art, and various gift packaging paper products and gift boxes.

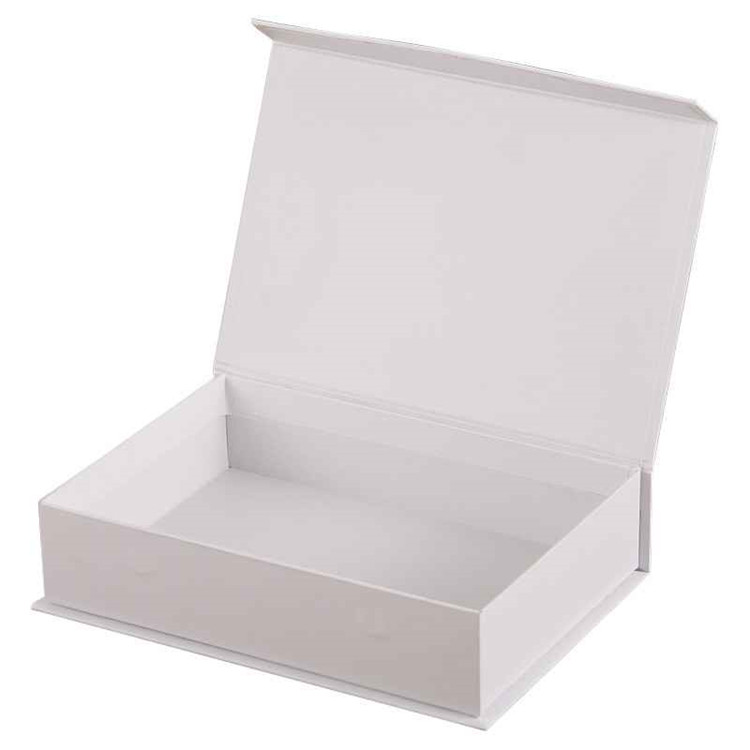

white paper box

Paper box is the most common type of packaging in paper product packaging and printing. The materials used are corrugated paper, cardboard, gray bottom, white card, and special art paper. Some also use cardboard or multi-layer light embossed wooden boards combined with special paper. Get a stronger support structure. There are also many products suitable for carton packaging, such as common drugs, food, cosmetics, tobacco, home appliances, hardware, glassware, ceramics, and electronic products.

luxury pa per box

per box

In terms of structural design, the carton should be changed according to the packaging requirements of different products. For the same pharmaceutical packaging, the requirements for the packaging structure of tablets and bottled liquids are very different. Bottled liquids require a high-strength, anti-extrusion cardboard combination to form a protective layer. The structure is generally combined inside and outside, and the inner layer is usually used. For fixed medicine bottle devices, the size of the outer packaging has a lot to do with the specifications of the bottle. Some packaging cartons are thrown away once used, such as household tissue boxes, which do not need to be exceptionally strong, but need to choose paper products that meet the requirements of food hygiene packaging to make the boxes, and it is also very economical in terms of cost.

custom paper box packaging

packaging

Tobacco boxes are representative of materials and craftsmanship. Hard-box cigarette packs use advanced white cards with fixed structure and specifications. In terms of printing process, many manufacturers choose more reliable anti-counterfeiting printing and cold foil processes. Therefore, the printing materials and printing technology with bright and beautiful colors and difficult anti-copying technology are more sought after by tobacco companies. There are also carton boxes with more complex structures and various materials, such as various gift packaging, high-end tea packaging, and even the once-mid-autumn gift box. Some packaging is designed to protect the product more safely and highlight its preciousness and luxury. Some are packaged entirely for packaging, and do not meet the practical functions of packaging described below.

As for the material used for the carton, cardboard is the main force. Generally, paper with a basis weight above 200gsm or a thickness above 0.3mm is called cardboard. The raw material for making cardboard is basically the same as paper. Due to its strong strength and easy folding, it has become the main production paper for packaging cartons. There are many types of cardboard, and the thickness is generally between 0.3 and 1.1 mm.

Corrugated board: Mainly consists of two parallel sheets of paper as the outer and inner paper, with corrugated corrugated core paper processed by corrugated rollers sandwiched between each paper sheet and the corrugated paper coated with adhesive on the corrugated peak. Corrugated board is mainly used to make outer packaging boxes to protect goods in the circulation link. There are also thinner corrugated papers that can be used as inner villages for commodity cardboard packaging to strengthen and protect goods. There are many types of corrugated paper, including single-sided, double-sided, double-layer and multi-layer.

White paperboard is made of chemical pulp and paper pulp. There are ordinary white paperboard and whiteboard, kraft pulp and whiteboard. There is also a kind of white cardboard made entirely of chemical pulp, also known as high-grade white paper.

Yellow paperboard refers to the low-grade paperboard made from the pulp produced by the lime method with straw as the main raw material. It is mainly used as a box core stuck in a carton for fixing.

Kraft board: made from sulfate pulp. Kraft paper on one side is called single-sided kraft paper, and kraft paper on both sides is called double-sided kraft paper. The main function of corrugated paperboard is called kraft boxboard, and its strength is much higher than ordinary paperboard. In addition, it can be combined with water-resistant resin to make water-resistant kraft cardboard, which is mostly used for beverage packaging boxes.

Composite processing cardboard: refers to the composite processing of composite aluminum foil, polyethylene, greaseproof paper, wax and other materials. It makes up for the shortcomings of ordinary cardboard and has a variety of new functions such as oil resistance, water resistance, and freshness.

Which type of cardboard is used, and what printing process is used? First, see if its material can meet the structural design requirements, and whether it can bear the strength required for the product during transportation, storage, and display. Secondly, it is necessary to check whether this type of cardboard can meet the required quality requirements of the product. Some products have strict requirements on the material properties of the packaging, such as some food or pharmaceutical packaging. Whether it can meet the printing and packaging process technology is also an important basis. High-volume packaging materials usually use high-speed roller gravure printing, flexographic printing, etc. Sometimes, post-press processing becomes a factor that restricts material selection, because high-speed and accurate die cutting, cutting or other post-press processes are very common in modern packaging.