Classification of laser card paper

Classification of laser card paper

There are two kinds of laser card paper according to whether there is a film on the surface of the paper (that is, whether there is a film on the surface when you tear the card paper by hand) : The first kind is the laser film and the card paper are compounded together by Glue, the second kind is no film, there’s still a laser pattern on the paper.

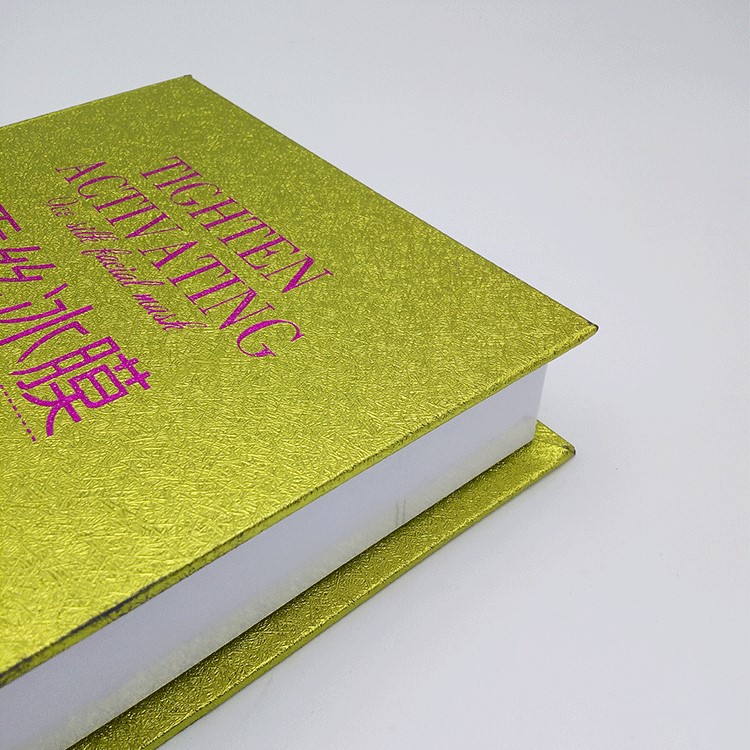

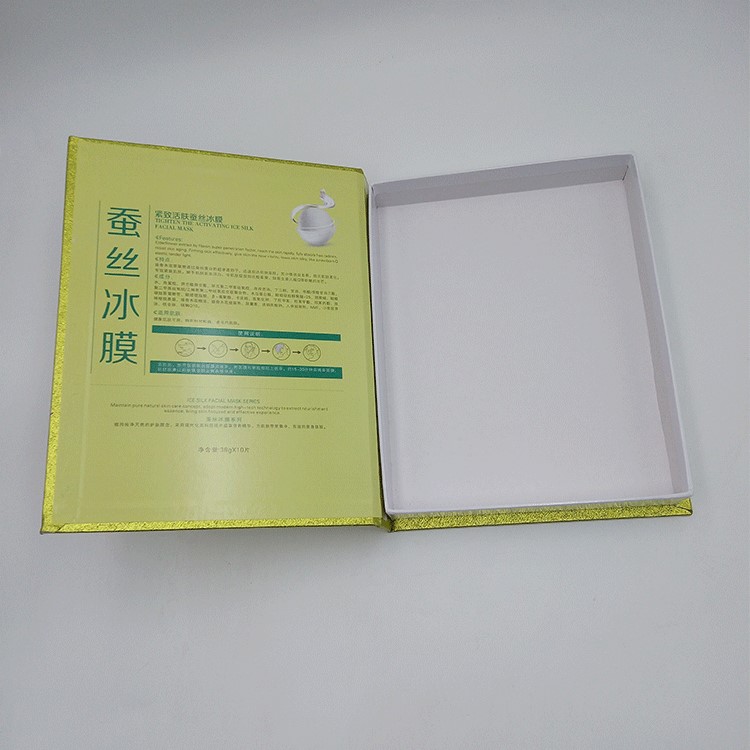

1. According to the material of the compound laser film, OPP can be divided into the compound laser film laminated cardboard and the compound laser film laminated cardboard. OPP LASER film laminated cardboard is relatively cheap, the original printing adaptability and the compound fastness is poor, because of the nature of OPP film itself, the surface corona value itself is not very high, and the corona value (the value) attenuation is relatively fast, basically 1 month began to decay, resulting in printing ink adhesion and glue compound fastness decline, prone to poor printing ink, laser paper in the beer box molding line position is easy to foaming, do high and low temperature aging test will have the phenomenon of foaming. But the PET laser film does not have OPP laser these shortcomings, on the contrary, the PET laser film surface corona value is high, the long time puts the corona value also not easy to attenuate. Printing adaptability is good, the disadvantage is higher price. OPP LASER card made by Xinyuan packaging uses water-based coating for cigarette pack and composite glue for OPP laser film, which solves all the shortcomings of OPP laser film and provides customers with stable quality and high cost-effective products. Compound laser card paper is mainly used in cigarette box, wine box, gift box, wrist bag and other packaging products.

2. There are two kinds of laser card paper, one is transfer laser card paper and the other is aluminized laser card paper. The first use of transfer laser card paper in the tobacco industry packaging, production process for laser transfer film and paper through the glue compound together, and then through the oven heating, the glue matures after the surface of the film peeled off, the laser pattern transferred to paper, it’s a truly eco-friendly, biodegradable material. Transfer Card with high gloss, high brightness, printing adapt to the advantages of good, the disadvantages is high price. Now generally the main application of label printing and blister packaging. Xinyuan packaging joint professional blister oil manufacturers, joint development, production of transfer card to solve the problem of plastic fragile easy to fall off. Product quality is stable, suitable for all walks of life blister packaging.

Laser card paper according to the pattern is divided into three main categories: the first: Plain laser card paper, the second: Beam Laser Card Paper, the third: Pattern laser card paper.

1. Plain faced laser paper Jam. That is, there is no pattern on the surface, but under the irradiation of light issued a colorful light.

2. Beam laser card. That is, the surface of a bar of the same size, at different angles to see, the light column will shake. According to the direction of the light rod grain is divided into cross-grain light column, straight-grain Light Column, twill-grain Light Column (45 degree twill-grain light column and 135 degree twill-grain Light Column) . According to the film surface is not a shading, divided into 100-point light column and 400-point Light Column, textured light column three.

3. Patterned laser card. That is, the surface is a variety of patterns, letter far packaging can produce more than 100 kinds of patterns of laser card paper, but also according to the guest sample to make a special version. The cost of General Open edition is about 5000 yuan.