What is the carton packaging production process?

What is the carton packaging production process?

First of all, to make a carton package, you need to box custom packaging know whether your product is suitable for carton packaging. For example, liquid, grease products are not suitable for paper packaging, easy to deteriorate, short-term food should not be directly Packed in paper because the carton custom lipstick packaging pack is gift paper box not easy to seal. Knowing that your bottle packaging paper product is suitable for packaging in the carton mode, you must compostable paper packaging clearly position the market price of your product, and calculate the approximate cost range of your product packaging by using the terminal price to further confirm what paper is suitable for use. What style of carton packaging.

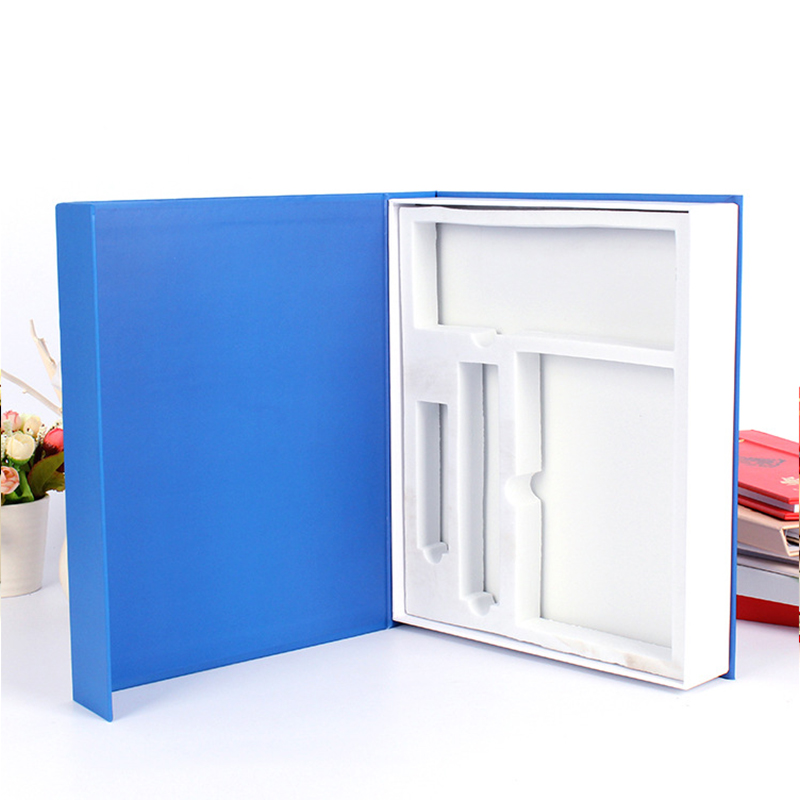

Well, with wine gift box these general concepts, you need to find a professional carton packaging design company, tell your designers and designers to chocolate gift box confirm the feasibility. And discuss with the designer the form of packaging design, performance content. The carton packaging designer will design the graphic and style according paper bags wholesale to your ideas in combination with the cost and the condition of your product. After designing, after proofreading and confirming the gift bags paper content of the graphic, it will enter the carton packaging production process.

The first step in the production brown paper bags for food is to make a plate by the plate-making staff. This step is especially important. The quality of custom kraft paper bags the plate-making directly affects the effect of the post-packaging. In this step, the plate-making division will separate the special processes such as printing content, bronzing content, silk screen and so on. Convenient for low cost paper bag post-production overprinting and reduce finished defects. After making a good version, the first step is military water bottle carrier to enter the paper-opening process. The paper opener will cut the appropriate paper size according to the actual paper condition to avoid waste. After you open the paper, you can print the design graphic onto the paper on the printing machine. After printing, it should be electronic lunch box fully dried paper carrier bag to avoid grinding and then laminating, silk screen, bronzing, die-cutting, bonding and other processes. A carton packaging production coloured paper bag is completed.

Many customers don't understand the carton packaging production process. Ordering today, tomorrow's goods, is unscientific. Every process takes time. It must bottle carrier with handle be prepared, applied, and brown kraft paper soap box quality checked to ensure quality. Many small In order to receive orders, the factory has severely reduced the construction period, has no preparation work, and has no quality inspection cosmetic gold storage box links. As a result, the finished packaging products have no quality, rough drawer kraft paper box details, and ultimately lose the sales volume of customers' products. Happy packaging carton packaging production will not be cosmetic box inner packaging rushed to work diamond paper box quickly, can not guarantee the normal cosmetics cotton pads box construction period of the single, the quality does not meet the standard goods oem paper box cardboard pill box are not paid, excellence, only for the fine, need carton packaging production please box package for cosmetic consult happy packaging, product sales are guaranteed !