What Are The Factors Affecting The Quality Of Packaging Boxes In Packaging Printing?

What Are The Factors Affecting The Quality Of Packaging Boxes In Packaging Printing?

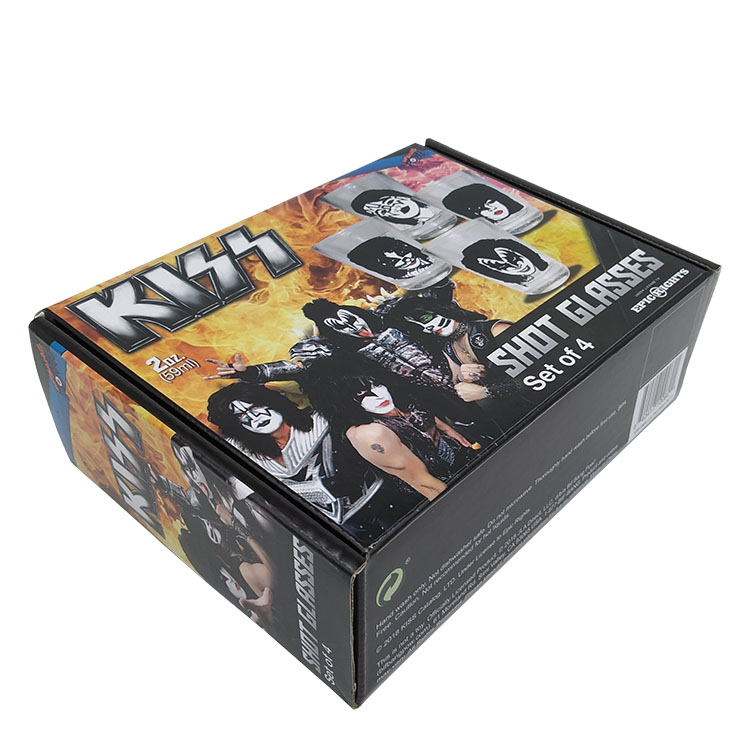

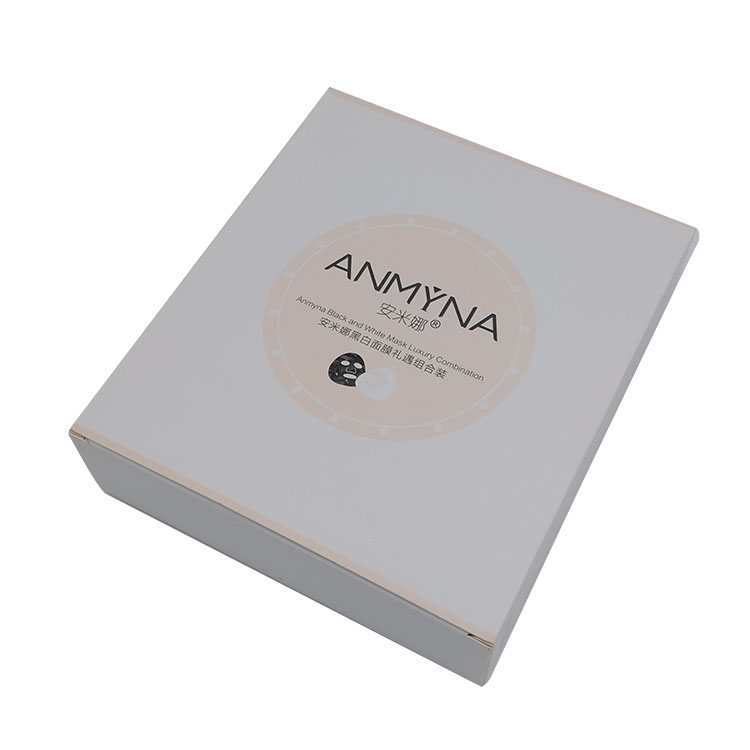

paper box supplier

As one of the packaging tools for various products and commodities, the packaging box is loved by majors. At the same time, the packaging box is also loved by consumers for its high-end, exquisite, and beautiful. Therefore, the major professions also pay great attention to the printing quality of the packaging box. So, how can the box printing factory control the printing quality of the box?

First, the impact of paper on packaging printing quality.

In the process of packaging and printing, due to the different properties of different papers, different papers are suitable for different packaging requirements; we have also introduced in previous articles that the amount of ink required for different papers also has different requirements of.

recyclable paper box

Paper with a high degree of smoothness requires a relatively small amount of ink, and paper with a poor degree of smoothness requires a relatively large amount of ink. Under the conditions of the same kind, same quantity and same price, the paper with higher smoothness and whiteness has better printing quality than the paper with lower smoothness and whiteness.

Second, the printing process affects the quality of packaging printing.

black paper box

During the printing process of package printing, the quality of the printing process will be affected due to the intensity of the light source, the interval between the light source and the plate, and the length of the exposure time. When the light source is strong and the interval is short, the moment we need to expose is relatively short; when the light source is weak and the interval is long, the moment we need to be exposed is relatively long. Under a certain light source and interval, with the increase of the exposure time, the film differentiation of the light-seeing part of the plate is increased, until the film face of the light-seeking drug is completely differentiated.

Third, development also affects the quality of packaging printing.

fold paper box

The development (printing, photocopying, copying, photo printing and other occupations, the process of flashing the image) is too long, and the drug-free film surface of the printing plate is easily dissolved, and the printing plate text will become lighter and thinner, forming a print The print is not true and clear. The development time is too short, and the surface of the drug film that is light-differentiated is not easy to completely remove, and it is easy to get dirty when printing. The density of the development also determines the quality of the box.

cardboard paper box

Fourth, the printing pressure has a great effect on the quality of packaging printing.

Printing pressure refers to the mutual force between the plate cylinder and the rubber cylinder, and between the rubber cylinder and the impression cylinder. It can be known that the size of the printing pressure will determine the final presentation effect of the packaging box. Different printing papers require different printing pressures. Only the appropriate printing pressure can ensure that the ink color is uniform and light and dark.

Fifth, the appropriateness of the printing plate determines the final quality of packaging printing.

The intended quality of the printing plate base sand, the hydrophilicity of the metal plate surface, and the lipophilicity of the coated polymer resin film surface are related to the suitability of the printing plate and affect the ink handling and the plate water-ink balance. In the process of making plates, the quality of exposure and development will also affect the performance of the printing plate.