Application Areas And Printing Points Of Screen Printing

Application Areas And Printing Points Of Screen Printing

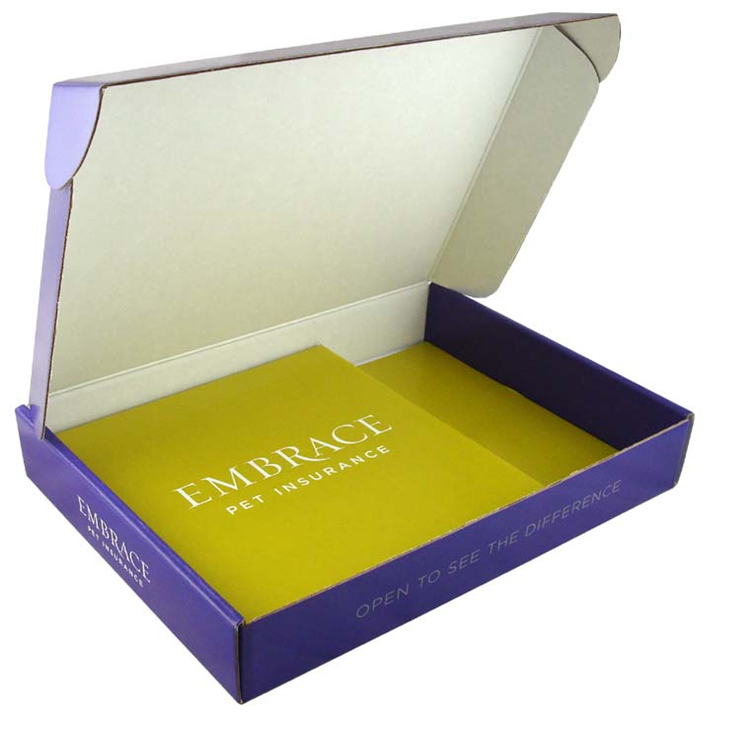

Screen printing is widely used. No matter from ordinary carrier printing, special ink printing to high-tech anti-counterfeiting printing, screen printing plays a huge role in the commercial print market. Such as integrated circuit boards, conductive circuits in industrial products, metal products shells, various special-shaped plastic products of glassware, textiles and clothing, packaging and decoration materials, leather furs, prints, various office supplies and other materials surface printing processing. recyclable paper box

paper box manufacture

Especially in the field of special printing technology, screen printing plays an irreplaceable role in other printing technologies, such as various printing with anti-counterfeiting effects, special process printing and so on. In the field of anti-counterfeiting printing, silk screen light-changing inks, color-changing inks, heat-changing inks, fluorescent inks, etc. have been widely used in product labels, packaging and OEM listing. Special effect printing, such as common refraction, fog light ice, etc., is often used in cigarette packets, cosmetics and fashion packaging. paper box with window

Before designers understand various packaging printing processes, they need to pay attention to the main points of various printing processes. Before choosing screen printing, we need to grasp two main points: making film (non-forest) and screen printing. The number of film lines used for screen printing of paper is generally between 100-200 lines. The film side of the film is facing up (the side of the film is facing down during offset printing). paper box printing

In addition, whether it is using llustrator, Potoshop or other image graphics and typesetting software, the text part must be converted into a curve to prevent the font from being lost to the text deformation. When delivering the file to the output company, the file should be specifically accounted for as the screen printing period. paper box for clothes

When making screens, the use of good quality screens and suitable screens has a key effect on the quality of the finished product. For high-precision screen printing, it is recommended to use imported screens as screens.

The net frame is divided into essence, iron, copper, aluminum, and steel. The earliest use of wooden net frames is a frame suitable for manual operation, but due to easy deformation after water, Jiping has been replaced by metal net frames. At present, the most used aluminum frame on the market uses hollow aluminum profiles and has a moderate weight. Not easy to deform, good water resistance, easy to operate.

CTS is the English name of computer-to-screen for screen printing. (Computer to Screen) is the same principle as CTP for offset printing. CTS is also a new technology that enables screen printing from computer to direct output platemaking through computer technology. CTS began in the 1980s, and it has become very common to use CTS screen printing abroad. Due to the high price of imported screen printing output equipment and the lack of corresponding technical capabilities to develop the equipment in China, the promotion of CTS in China is still in its infancy.